14 December 2023 Aircraft Crew Seat Conversion NHAHS Office Update

Since we stripped out the entire SH-60F of items to make the aircraft as light as possible, most things were disposed of, while among things NHAHS has kept are the four pilot/aircrew seats from the helicopter. The plan was to make a desk chair conversion so these seats could be used in the future in the NHAHS/NHA/NHASF Offices in BLDG 654, NASNI.

Currently we have completed/converted two seats and are working on the final two seats. All four seats were pretty filthy after years of operational use plus 11 years sitting in the desert.

We first scrubbed the seat with hot water and dawn liquid dish soap. We then took the seat cushions and unzipped and removed the seat back and seating material(foam and hardback material) and ran the seat covers through a heavy-duty wash with extra soak time and several rinses using the hottest water temperature. We set the seat and the seat covers out to air dry in the sun.

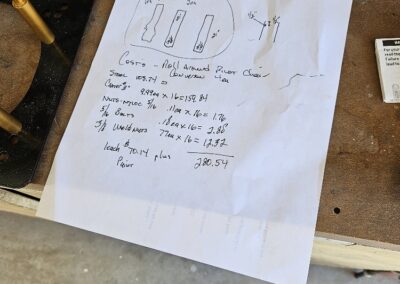

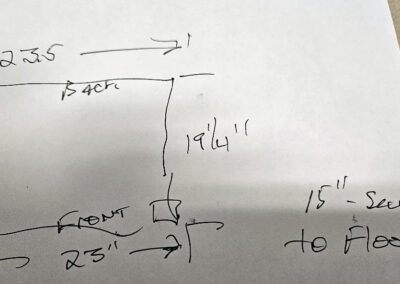

We used some spare leftover 1×1 inch and 2×3 steel material available to us to make a trial framework up in order to test it out. For the remaining three frameworks, we used just 2×3 steel to make the frames. We used 2×3 steel, thick wall to make a framework in a “H” shape. The 60B seats are roughly 23 inches wide and 19 1/2 inches deep. We used 23-inch length2x3 steel legs of the H shape with an 18 3/4-inch 2×3 steel center piece to connect the H together. After welding the H together, we centered the seat on the H close to the back of the H, with the H pointed forward. Four holes big enough for a 5/16-inch bolt were drilled in the top of leg of the H and four drilled in the bottom at each end of the H leg, large enough to accept a 4 3/8-inch weldnuts. The weldnuts were welded into the bottom of the H legs. After cleaning the metal, it was painted with black rustoleum paint. 4 3-inch stem casters with 3/8 inch course thread shanks were used, threading each caster into its respective weldnut on the underside.

We used four 5/6-inch x 1 inch course thread bolts with a Nylock nut installed in each top hole leaving the bolt loose with about 1 /2inch off threads showing. The seats frame was positioned and then slid over the four attachment bolt heads. The bolt heads slid into the built in 60B seat track. Once the seat was in position, each Nylock nut was tightened to secure the seat to the framework.

We have tested them here in the office and they sit and work pretty well.

SH-60 Helicopter Pilot-Crew Seat Office Chair Conversion Plans